Zirconium-doped (9%) alumina ceramic offers thermal conductivity 1.1 times and flexural strength 1.7 times that of standard alumina products. It is primarily used in medium-power modules requiring higher reliability, such as automotive applications.

High thermal conductivity materials with a thermal conductivity seven times that of standard alumina products. These are primarily used in high-power modules, wind turbines, locomotives, power electronics, and more.

High-performance alumina ceramic with flexural strength 1.28 times that of standard alumina products, mainly applied in industrial control and medium-power modules.

AMB (Active Metal Brazing) substrates feature higher bonding strength and greater reliability, making them ideal for IGBT module packaging in electric vehicles and locomotive applications.

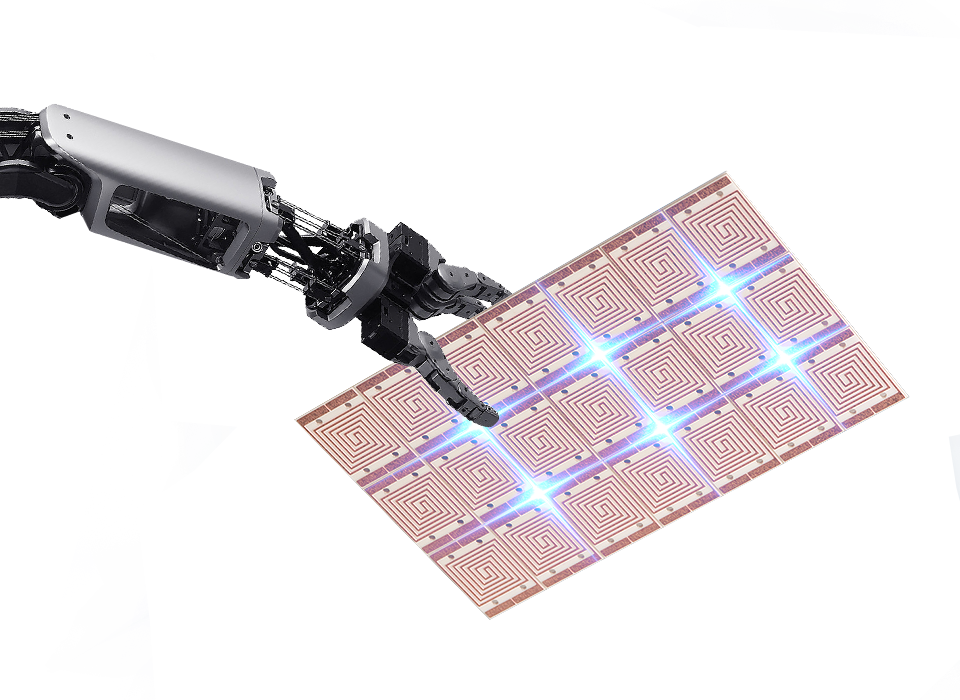

DCB (Direct Copper Bonding) is an electronic base material formed by directly sintering copper foil onto a ceramic surface. It has excellent thermal cycling performance, high mechanical strength, high thermal conductivity, high insulation, and the capability to carry large currents.

We remain committed to continuous product development and process improvement. By maintaining strong, long-term partnerships with prominent research institutions and academic organizations both domestically and internationally, we lay the groundwork for elevating our products and processes to the ranks of world-class excellence.